|

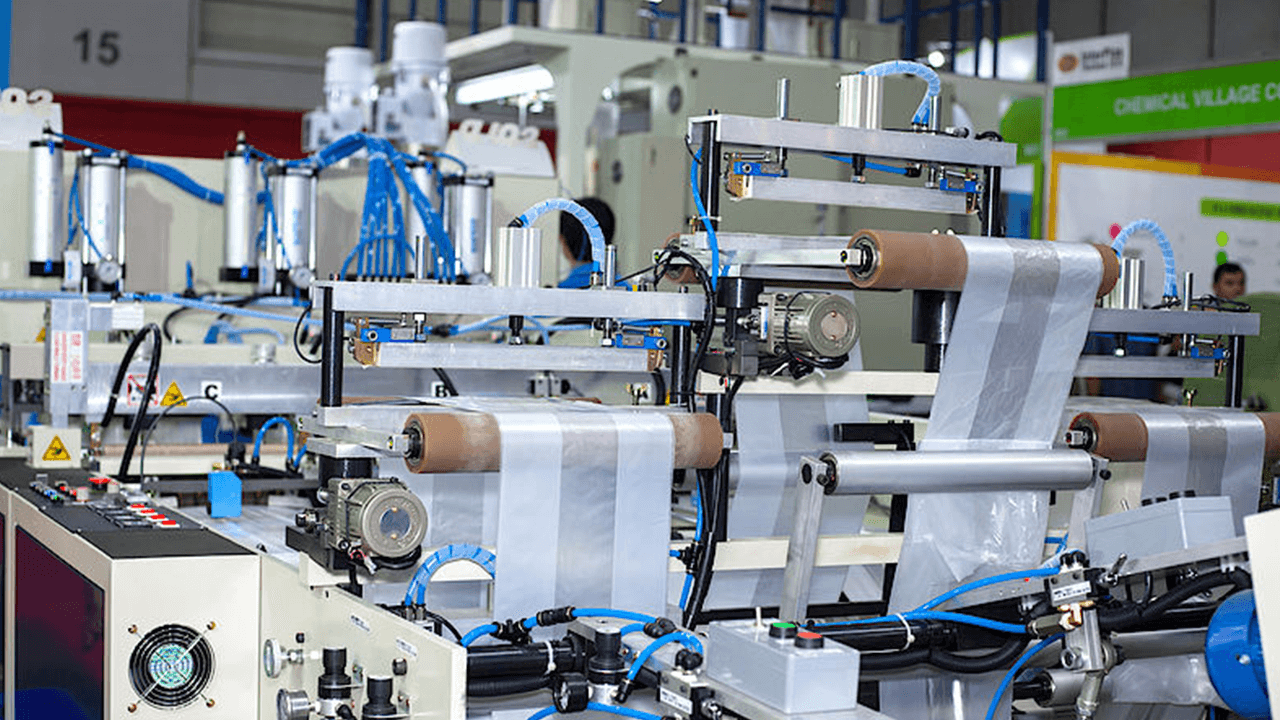

During this period we exported tens of thousands of extruders, bag making machinery and printing machines all over the world, anywhere from South East Asia to countries such as Nigeria and Poland. This means that if you have plastic bag related machinery in your factory, it could be a Dipo made machine that has been rebranded! Brand Development For the past 7 years we started to attend fair shows under our own brand name. This allowed us to build our own after sales service network and agents in every continent. Our past experience as an OEM manufacturer enabled us to acquire the knowledge to make German quality products and to produce a full range of bag making machinery including blown film extruders, bag making machines with cutting, sealing and folding capabilities, flexographic and rotogravure printing machines and automatic bag packaging machines. Global Services Success in trade fair shows, has led us to have an ever expanding global distribution network that now includes agents and distribution centers in the following areas: Thailand, Vietnam, Indonesia, Egypt, Argentina, Russia, Turkey, Nigeria, El Salvador, The Philippines and other places around South East Asia, Europe and Africa especially. So it doesn’t matter where in the world you are, we can help you to maintain and service your printing machines, glove making machines, autopacking machines, pick up bag making machinery and anything else from our product range. Making A Difference Now instead of building machines purely for profit. We want to use the Dipo brand to make a difference to the world. We understand that plastic waste is becoming more and more of a problem around the globe, and want to leave a better environment for our grandchildren. Lots of companies say this, but we put actions behind our words. Aside from the normal types of raw materials, such as HDPE, LDPE and PP, our research and development team work on processing recyclable material such as thermoplastic corn starch (TPS). Because of the expertise involved in processing, not all companies have the knowledge to run this type of machinery. A lot of our partners know that their customers want to be involved with eco-friendly companies and this all starts from the machines. With current recyclable and biodegradable films and bags, the machine is heavily dependent on the raw materials used, with natural products, different soil content and conditions lead to materials that might not be processable by the current machinery without modification. We have experience in all of these issues and can advise customers on how to store the raw materials, where to buy suitable material how to modify the bag making machinery that we provide, and even how to tweak the base materials leading to different rates of decomposition. Translating Our Dreams Into The Real World An example of this is how companies specializing in compostable and biobased plastics have been searching us for our expertise. Our machinery has helped companies to produce products that achieve EU and American EN13432 and ASTM D6400 compostable plastic certification standards. We also conduct research into changes in the foreign markets. Take the French and Italian government regulations. Now there are regulations requiring all compostable bags to be home and industrial compostable with a biobased plastic content of at least 40%. Dipo stands out from the rest of the bag making machinery market as our engineers already have experience in achieving and surpassing these stringent requirements so you can be safe in the knowledge that if you purchase Dipo biodegradable plastic bag technology, your products will be some of the most eco-friendly on the planet. Your consumers will have the confidence that the plastic bags that they use will not produce the microplastic pollution that destroys the environment, but be able to naturally decompose by organisms into CO2 and water. Business Project

Comments are closed.

|

Industry PPE NewsAll the latest news about plastic processing equipment you can get here. Categories

All

A knowledge platform established for industry

|

RSS Feed

RSS Feed